Equipment

Cutting-edge equipment provides high quality at a low cost—and with quick delivery times.

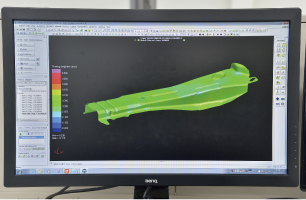

Creating high quality and highly precise metal molds that support the evolution of manufacturing technologies requires constant equipment enhancement. We continue to install cutting-edge equipment such as 3D solid CAD/CAE analysis and 1,500 ton presses equipped with coil feeders, and create environments that match the manufacturing environments of our customers as closely as possible, to further increase the precision of our metal molds. We are also committed to creating clean work environments that are easy to work in. For example, we have installed air conditioning throughout the entire factory building.

Finishing #3 Factory

-

1500 ton mechanical tryout press

-

Coil feeder

-

Vertical machining center

-

Five-surface multi-center

-

FMC processing machine

Machinery Factory

-

Machinery Factory (bird's-eye view)

-

Gate type machining center

-

Gate type machining center

-

Machinery Factory (bird's-eye view)

-

Laser processing machine

Finishing Factory

-

Inside

-

1000 ton mechanical tryout press

-

600 ton mechanical tryout press

-

100 ton mechanical tryout press

Design/analysis room

-

Bird's-eye view

-

A meeting

-

NC data creation

-

CAE tool

Gunma Factory

-

Gunma Factory (outside)

-

Machinery Factory (inside)

-

Gate type machining center

-

600 ton mechanical tryout press

-

1200 ton mechanical tryout press